News

September 2023

DeJong adds two more robotic forming cells to meet customer demand.

July 2023

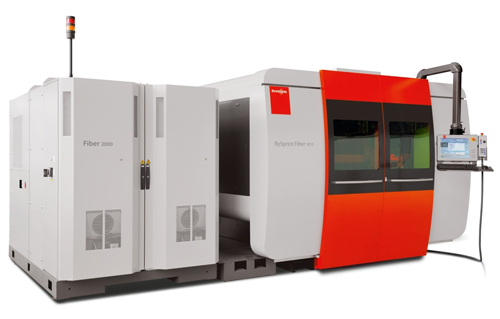

DeJong installs 30kw Fiber laser to the fleet of lasers for more productive plate processing.

June 2023

DeJong adds robotic painting to the portfolio to aid our team.

February 2022

DeJong received highest award with John Deere, being the only metal fab supplier to achieve Partner Status.

November 2021

Installation of the first 15,000 watt fiber laser in Iowa with supporting automation.

January 2021

Addition of another CNC forming cell to increase DeJong forming capacity.

April 2020

Installation of two robotic forming cells.

March 2020

Installation of intelligent warehousing system increasing flat sheet storage capacity allowing DeJong to stock 2.5 million lbs

February 2020

DeJong was presented with another Partner award for 2020 by John Deere.

December 2019

Installation of second 10,000 watt laser with automated part sorting. DeJong is the only fabricator in the entire United States to have two automated part sorting cells.

February 2019

DeJong achieved the prestigous 5 Year Hall of Fame award from John Deere.

December 2018

Installation of first integrated automated laser part sorting system for DeJong and a first in the State of Iowa.

February 2018

Partner Level status achieved with John Deere

March 2017

Installation of 10,000 watt fiber laser with automation

February 2016

Installation of an additional powder paint primer system which allows for two coat powder application for superior corrosion performance.

June 2015

Installation of new 6kw Fiber Laser with automation.

February 2014

DeJong Mfg receives another consecutive award recognition, the John Deere 2013 Partner award at the Deere AE Supplier Banquet in Davenport.

December 2013

DeJong Mfg is the proud recipient of a Supplier of the Year award from World Class Industries. WCI (Brent Cobb - WCI President) recognized DeJong for outstanding efforts in Quality, Delivery and Partnership. This is the 2nd time DeJong has received this award.

August 2013

DeJong adds a Fiber laser to the existing fleet of Bystronic equipment. A Bystronic 4kw 3015 Fiber with cellular automation was added to increase capacity and meet customer demand.

February 2013

DeJong Mfg is the proud recipient of a 5 year Hall of Fame award for achieving five consecutive years of Partner status in the John Deere Achieving Excellence program. DeJong was presented with the award recognition at the Deere AE Supplier Banquet in Davenport.

February 2012

DeJong Mfg receives another consecutive award recognition, the John Deere 2011 Partner award at the Deere AE Supplier Banquet in Davenport.

August 2011

DeJong adds an 11th laser to it's exisiting fleet of Bystronic equipment. A Bystronic 6kw 4020 with cellular automation was added to increase capacity and meet customer demand.

June 2011

DeJong installs a bi-directional folding system for large bent product. A new Fasti up/down folding system was installed for more efficient forming of large product. The system is capable of forming up to and including .25" plate at 10ft long.

February 2011

DeJong Mfg recieves the prestigious John Deere 2010 Partner award at the Deere AE Supplier Banquet in Davenport.

May 2010

DeJong selects Bystronic as the preferred supplier of press brakes for the "standardization" project. The six Xpert press installations will bring increased productivity along with supporting aspects towards six sigma quality initiatives. DeJong currently has presses ranging from 60ton to 400ton and has plans of installing more Xpert presses in the near future.

February 2009

DeJong receives highest awards at John Deere Supplier Banquet in Davenport. DeJong was awarded 2008 John Deere Supplier of the Year - Global Hay and Harvesting Award. This was only one of four Supplier of the Year awards presented to the entire John Deere supply base worldwide. Bonnie DeJong, Company President quoted "It is quite an honor for John Deere to recognize us again for such a prestigious award. It is a testamant to the talented individuals we have on our team and the great relationship rapport shared with the entire John Deere staff. I could not be more proud of everyone that contributed to this award."

January 2009

DeJong completes the addition of a new state of the art Powder Coating facility. Joel DeJong quotes "This new line will give us a competetive advantage over our competitors and our previous system. With quick color changes, powder reclaimation and two different energy sources for curing, at this time we have a system no one else can offer in our area."

October 2008

DeJong breaks ground beginning construction for a new state of the art Powder Coating facility, the first one of its kind in the United States. This facility will replace the current powder coating operation along with being isolated from manufacturing operations. This investment will give DeJong and customers an operation capable of coating larger products, quick change color, and ability to reclaim powder. The line also contains multiple energy saving oven configurations. The new revolutionary powder booth design is the first one installed in the United States. We are looking forward to the first powder coated parts coming off this production line in January 2009.

May 2008

DeJong installs new 6kw laser being the highest wattage tubular processing machines in the Midwest.

March 2008

DeJong installs new Haas vertical machining center to add more machining capacity for customers.

January 2008

DeJong installs a new 4.4kw Bystronic Laser with automation - "the first of its kind in the United States"!

February 2007

DeJong was awarded the John Deere FIVE Year Partner Supplier Award for obtaining 5 consecutive years as a Partner supplier within the Deere Agricultural Division.

November 2006

DeJong installs a two Bystronic 6.0KW lasers. This will add capacity being number ten of laser processing cells at DeJong. This 3015 (1.5 meter x 3 meter) machines have the ability to cut up to 1" HR plate, .375" aluminum and .625" stainless. This cell also consists of automated load/unload for "lights out" processing. DeJong is excited to have the first 6kw Bystronic in the Midwest to assist valued customers.

October 2006

DeJong moves in to a newly constructed 30,000sq/ft warehouse. The warehouse also houses a tornado shelter for all employees in an emergency weather condition. The shelter was built from concrete with reinforced steel with a roof plate made of 1" steel. The added square footage will allow DeJong to stock more raw materials for customer and allow DeJong to grow to meet current and future customer demand.

June 2006

DeJong breaks ground and begins construction of a new warehouse.

October 2005

DeJong installs a 4th Bystronic 5.2KW laser. This will add capacity being number eight of laser processing cells at DeJong. This 4020 (2 meter x 4 meter) machine has the ability to cut up to 1" HR plate, .375" aluminum and .5" stainless.

August 2005

DeJong installs and begins testing of new Wila European precision ground quick change press brake tooling. This new tooling will allow DeJong customers to avoid most tooling charges related to formed product and will shorten leadtimes.

March 2005

DeJong receives highest award at John Deere Supplier Banquet in Davenport. DeJong was awarded the 2004 John Deere JD Crop Ag Division Award for submitting the most cost reduction opportunities for the Deere Agricultural Division. Representing DeJong were Bonnie DeJong, Joel DeJong and Kevin Lamb.

January 2005

DeJong installs a 2nd Byspeed laser processing cell for increased sheet metal processing capacity. This machine was configured with a 5200watt Bystronic resonator with sheet/plate automation for loading of raw material & unloading of finished product. The added wattage along with the automation will give DeJong customers a competitive advantage in product pricing and quality along with adding laser capacity for DeJong customers.

December 2004

DeJong installs a 2nd Bystronic 5.2KW Bystar3015 laser. Such high power will add laser capacity for DeJong and their customers in thick plate processing of parts.

December 2004

DeJong installs new automatic CNC Hem Saw. This new purchase will assist DeJong and its customers in sawing larger products and tubular product with mitres more efficiently. The saw is capable of doing 60 degree mitres and bundle cutting to customer required lengths.

November 2004

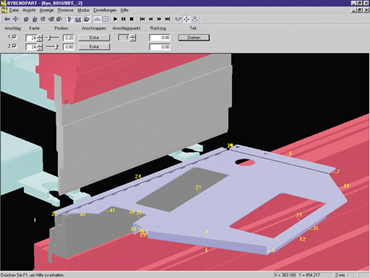

DeJong installs and begins testing of offline press brake programming software to increase forming efficiencies and to shorten product delivery time to our customers.

October 2004

DeJong installs new CNC Vertical Machining Center. A new Haas VF5 was purchased and installed to assist customer needs of adding machined detail to laser, plasma cut and welded products.

September 2004

DeJong installs our first Bystronic 5.2KW laser which will be the first and largest Bystronic resonator to be installed in the United States. Such high power will help DeJong and their customers in thick plate laser processing of parts.

September 2004

DeJong product seen in the news. As seen on The Iowa Channel, laser cut artwork can be seen on the "Sweetheart Bridge" on the Central College campus in Pella.

May 2004

DeJong receives ISO9001-2000 certification.

February 2004

DeJong receives highest awards at John Deere Supplier Banquet in Davenport. DeJong was awarded 2003 John Deere Hay and Harvesting Supplier or the Year Award. DeJong was also awarded the JD CROP (John Deere Cost Reduction Opportunities Process) award from the Deere Agricultural Division.

February 2004

DeJong installs pass through shot blasting system for laser oxide removal and for white metal surface preperation. This machine will compliment our seven laser cutting cells and plasma shape cutting cell to offer our customers superior surface finish that will allow for improved weldability and enhanced paint quality.

November 2003

DeJong begins testing of a robotic press brake install capable of handling, forming and stacking over a 100lb part with no human intervention. This investment was made to reduce worker repetative motion, increase part quality and reduce the amount of labor required in our forming cells. This will reduce part costs, thus saving our customers money!